Optimal control by proper maintenance of ventilation systems

Tips & tricks for maintenance of your poultry or pig house ventilation system

How can you keep your ventilation system running within optimal parameters?

During the summer season, ventilation systems get dirty fairly easily as periods of drought can kick up lots of dust. Together with the dust coming from inside the house, ventilation systems can get pretty dirty and thus is proper maintenance of your ventilation system necessary. We have some tips and tricks for maintaining a properly functioning system.

– During installation make sure to mount the inlets on a flat wall/ceiling surface and make sure to caulk the left-over spaces around the edges of the inlet with a flexible silicone sealant. Do not use other foams or fillers as these might cause the inlets to jam as they have different expansion values.

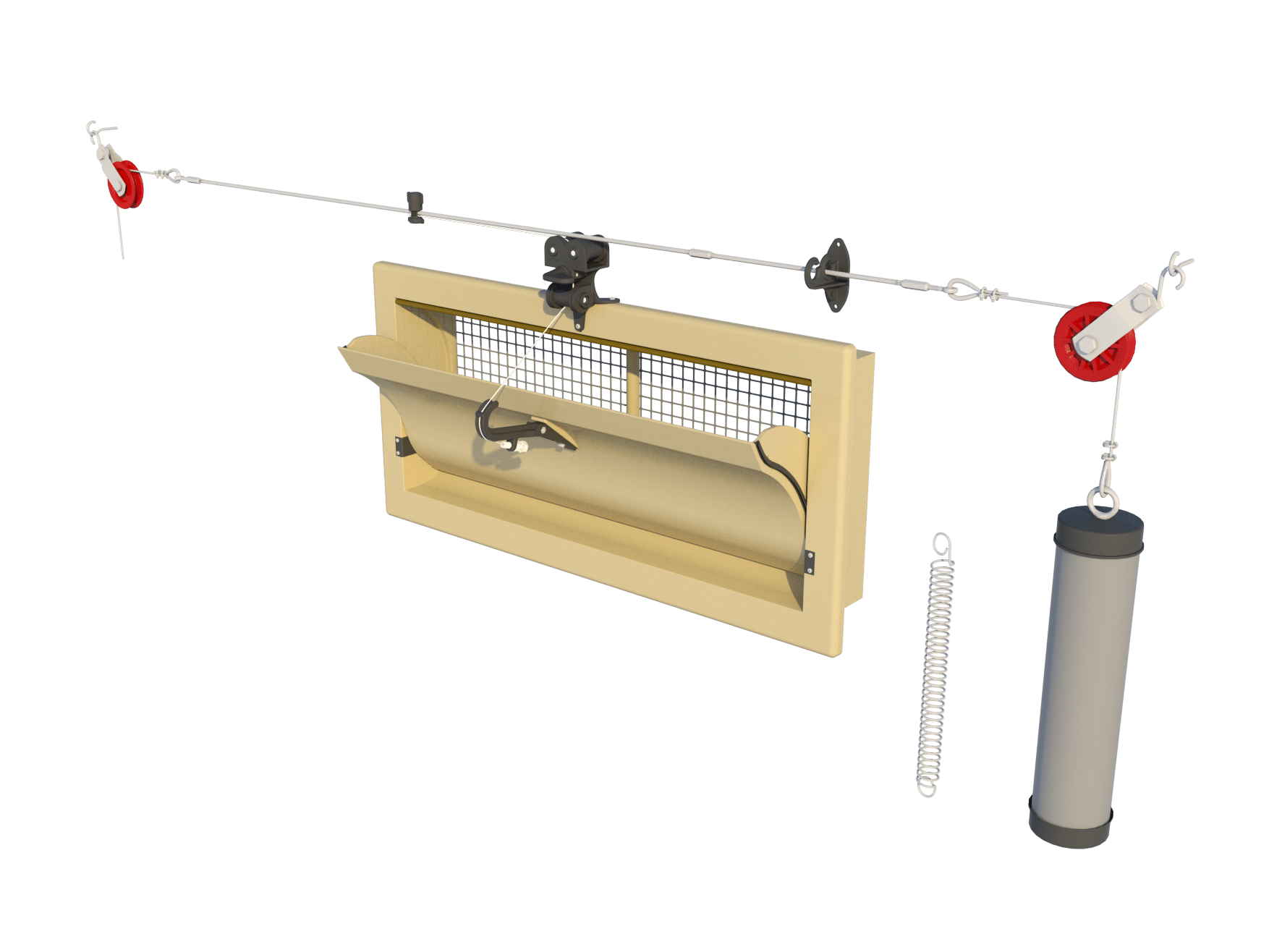

– After cleaning make sure to check up on the inlets and see if they still open and close well. To make sure all inlets are in the correct and same setting we advise the following, close the inlets and then make sure the connection to the main cable is under the correct initial tension as other inlets are. (adjustments can be made with the cable clamp to make sure everything is tightened)

– When transitioning from summer to autumn it is important to see if under the new circumstances the air is still correctly guided upwards to the roof. This way you can prevent having a cold airdrop onto the animals. When in doubt you could verify by doing a smoke test to guarantee that after the settings have changed there still is a nice spread of air throughout the house.

– When using light traps and wind hoods we suggest to regularly remove these from the wall and clean them. Light traps can gather quite some dust and debris between their sheets.

– Pay close attention while cleaning the inlets, avoid using corrosive cleaning solutions that might harm the polyurethane. Also make sure not to use too much pressure with the pressure washers as it might damage the skin of the inlets. Use max. 1740 PSI at a minimum distance of 10cm and temperatures not exceeding 50 degrees Celsius.