Keeping optimal control over the indoor climate of poultry houses in tropical areas

A short guide on poultry housing and ventilation in tropical areas

This white paper is about how birds react to indoor climate conditions and what that means for heat management inside a poultry house. In a way, it is a guide to what extent ventilation parameters are important when designing a poultry house. Having an optimal indoor climate will reduce heat stress in poultry production in hot and humid climates.

Table of contents

– Introduction.

– Climate conditions.

– Designing a poultry house where you can control the indoor climate.

– Why does heat stress happen?

– What can I do to avoid heat stress?

– The optimal house.

– Tunneling is important for cooling.

– Conclusion.

Introduction

Most of the population in the tropics depends on poultry as their significant source of protein supply. The harsh climate conditions in this region are making it harder to have optimal performance in poultry production. This results in a lesser everyday supply of protein. In the past few years, poultry production has had an important role in the global agricultural industry. Asia, South America, and Africa are reporting quick growths in poultry meat production. Rapid urbanization, poverty, and hot climates are typical for these regions. The trend is that the growth will continue as it is the fastest way to close the protein supply gap. In tropical areas, most poultry is kept in open houses as they are easy to build without a lot of costs. But is it the optimal way to approach efficient poultry production? Or can the yield be improved significantly when investing in a closed house system with an optimal indoor climate?

Climate conditions

Climate conditions

Extreme weather conditions in the tropical regions of the world have proven generally harmful to livestock production. Especially for chickens as they are highly sensitive to temperature changes. Like mammals, the avian species can regulate their body temperatures by losing or generating heat in response to the surrounding temperature. The normal temperature for a bird is between 39°C and 40°C. If it rises above these numbers, the birds will not perform well. These climate circumstances are responsible for the so-called “heat stress” effect. Heat stress in poultry production can result in under-nutrition, delayed growth, reduction in egg production and size, laying of premature eggs, and even death. This issue worsens by the high body heat generated by genetically improved laying birds with increased metabolic activity resulting from the high rate of egg production. It is good to read about how you can recognize when heat stress occurs in the birds.

“local climate conditions and weather extremes dictate the design of the ventilation system”

Designing a poultry house where you can control the indoor climate

The way the poultry house is designed has a large impact on the interior climate conditions. These in turn can have a positive or negative effect on the health, growth, and performance of the birds inside. Although often overlooked, the way of ventilating the poultry house plays a key part in creating the optimal indoor environment for the birds. There are lots of natural ventilated (open) poultry houses in tropical areas, because of the simplicity to build them and the minimal costs, they do not give the best options for controlling the indoor climate. Another problem with using open houses is that they are prone to all sorts of pests, like rats and wild birds, which can become an issue with diseases. This type of housing offers no insulation and weather influences can hurt the performance of the birds. The better option is to have a closed house with mechanical ventilation.

A bit more about birds.

A bit more about birds.

Birds are warm-blooded ‘homoeothermic’ feathered egg-laying vertebrates that possess a high metabolic rate with a normal breathing rate of 40–50 breaths per minute. On average birds maintain an internal body temperature of between 39 and 40°C. When the weather is hot, they maintain a thermal-neutral temperature by losing heat mainly through conduction, convection, radiation, and evaporative cooling.

Why does heat stress happen?

Sensible heat loss through convection, radiation, and conduction is only effective if the surrounding temperature is below or within the bird’s thermal-neutral zone. However, evaporative cooling accounts for about 60% of the heat dissipated during body temperature regulation within the thermal-neutral zone. Sensible heat loss includes heat loss through opened surfaces such as wattles and other featherless areas around the neck and wings. Heat loss for body temperature regulation through this process does not alter the bird’s behavioral patterns, feed intake, or metabolism. The effectiveness of sensible heat loss is depending on the temperature difference between the bird and its surrounding.

Where the surrounding temperature exceeds 24°C evaporative cooling becomes the major method of dissipating heat in birds regardless of their age. Loss of heat through evaporative cooling at temperatures beyond the thermal-neutral zone requires the bird to redirect the energy required for growth and development to panting. However, panting can lead to dehydration because of inadequate water intake and a drop in blood pH due to excessive ejection of carbon dioxide.

During panting, evaporative cooling occurs when water evaporates from the respiratory system of the bird. Note that this process can be hindered by high humidity. This can be problematic in high humid environments where poultry farmers employ evaporation cooling as the primary method of air-temperature reduction during the hot periods of the year.

“Birds eat and drink less when they are in heat stress and that affects the yield”

What can be done to avoid heat stress?

Increasing the volume and velocity of air moving over birds enhances heat loss in birds due to convection. Removing the heat trapped within the poultry house and reducing the effect of high humidity on evaporative cooling. Birds eat and drink less when they are under heat stress and that affects the yield. Therefore it is very important to provide and maintain the required ventilation to ensure that the indoor climate of the poultry house is helping the birds to regulate their body temperature by sensible heat loss.

● Panting & Rapid Breathing

● Pale Combs/ Wattles

● Loss of Electrolytes

● Wings Outstretched and Feathers Erect

● Bird Stop Eating & Drink Large Amounts of Water

● Diarrhea

● Chicken Becomes Droopy

● Decrease in Egg Production Decreases, Thin Shells

● Staggering, Disorientation, and Seizures

● The collapse of System and Death

If nothing is done to cool the birds, they will die from

organ failure due to dehydration and heat.

The optimal house

It becomes clear that the best performing house is the one where you will have complete control of the environment inside. The mechanical ventilated housing solution has a better yield. Insulation helps to keep the house cooler during the hot weather as well. This means that not only the walls and the roof should be insulated, but also the components that connect the outside with the inside. So having insulated air inlets or tunnel doors can have a beneficial impact on the inside temperature. For cooling, it can help to spray water on the roof of the house. Also, closed houses allow for far more control over air exchange, airspeed, and the direction of the airflow. It is imperative that the poultry house is airtight.

The air inlet system automatically opens in case of a power failure. This then allows fresh air to easily come inside the house.

The location of the air inlets inside the house is important. Not only the height where they are put into the sidewalls, as well as the distance between them, can dramatically improve the airflow and dispersion inside the poultry house. Take note of the air inlet design. The design differs depending on the type of birds inside the house. When looking at broilers kept on the ground the inlets need to give you the perfect control. With broilers in cages, it is important that the air-flow refreshes everywhere in the house. With breeders, you should not get a draft in front or inside the nest boxes as the birds will not go in and when looking at layers in aviary systems the air flows over the aviary as well as under the system, depending on the situation in the house. It becomes clear that there is more to be said about the ventilation system than just putting inlets in a wall. A rule of thumb is that at cooler times the inlet should direct the air towards the ridge of the house (the cooler air can then mix with the warm air at the top of the house) when it gets hot the air inlet should direct the air more towards the animals. It is because of this that the inner flaps of the inlets need to have an aerodynamic shape to guide the air to where it is needed most according to the climate situation inside.

Tunneling is important for cooling

Tunneling is important for cooling

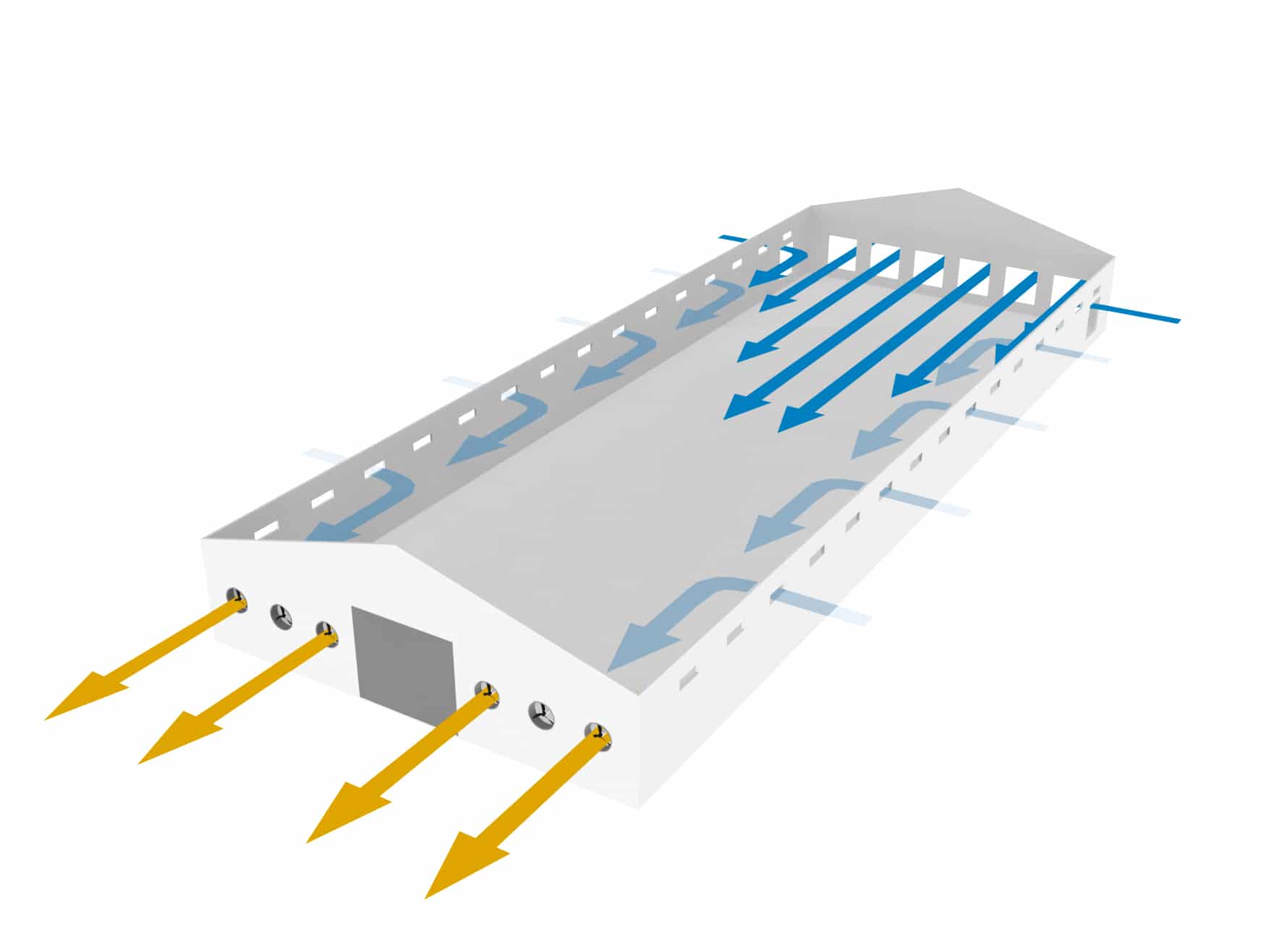

The best practice is to have a combination of sidewall air inlets combined with tunnel ventilation. Tunnel ventilation is used for having greater airspeed through the house. Use cooling pads together with the tunnel units to have an effective cooling system in place. These pads should not be positioned directly at the tunnel units. Preferably there should be a small doghouse build around the tunnel unit areas. The cooling pad area is larger than the tunnel opening. This allows a lower airspeed through the pads. The airspeed will become higher when going through the tunnel unit. This is due to Bernoulli’s Principle.

“Bernoulli’s principle states that as air moves from a wider pipe to a narrow one, the air begins to move faster.

This is how the high airspeeds can still be achieved inside the house and the airspeed through the evaporative pads

will stay low. In this way, the water droplets are not blown through the pad into the house. This, in turn, helps to

keep the litter in good condition.”

Conclusion

Heat stress is one of the reasons why a poultry house is performing badly. It is good to know how to spot the changes in the behavior of the animals that are in heat stress. Even better is it to avoid that the birds go into heat stress. That is why in the areas where the environmental temperature is severely high and unbearable for birds the mechanical ventilated housing systems have been introduced. The combination of tunnel and inlet ventilation systems has been reported to sustain improved bird production in these areas, regardless of the extreme weather conditions.

Important to note is that to design an optimal mechanically ventilated house, attention should be given to the needed capacity calculation for the type of birds that will be in the house. The amount of heat generated by the birds, the sizes, positioning, and design of inlets and exhaust fans should match with the type of bird in the house. And finally the capacity of circulation fans required for the sidewall air inlet ventilation system. It is best practice to think about the ventilation system upfront while planning your house.

Sources:

Aviagen Ross Environmental Management in the Broiler House

http://en.aviagen.com/tech-center/download/236/Ross_Environmental_Management_in_the_Broiler_House.pdf

National Center of Biotechnology Information

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7206398/

Department of Poultry science, University of Georgia

https://www.poultryventilation.com/node/5118

A bit more about birds.

A bit more about birds. Tunneling is important for cooling

Tunneling is important for cooling