Combining ventilation concepts for very large poultry houses

In this white paper, we explain how ventilation systems can be designed for very large poultry houses. Poultry houses are getting wider and longer, which helps increase production but also creates new challenges for ventilation. Because of their size, using just one ventilation method all year isn’t enough. Combining different ventilation techniques helps keep the climate stable and improves the health and growth of the birds.

Small screen? PDF version available here

Table of contents

- Introduction

- Challenges of ventilating very large poultry houses

- How ventilation techniques work together for the best results

- Unique ventilation and climate factors in large houses

- Conclusion

Introduction

Ventilation has evolved as poultry houses have grown in size. Larger buildings require more thoughtful ventilation designs because they often include support structures that can block airflow. Proper ventilation is essential to create a stable and healthy climate inside the house throughout the year. That’s why ventilation should be considered from the start of the design process.

Challenges of ventilating very large houses

Over the past decades, poultry houses in the US have increased from about 16,000 square feet to nearly 40,000 square feet, with widths growing up to 78 feet (24 meters) or more. These larger dimensions require more complex ventilation systems. In some parts of Asia, multistory poultry houses show that upscaling continues worldwide.

Upscaling

Growing farm size has always been a way to increase production and profits. In China, multistory buildings with integrated manure processing and slaughterhouses are common. In other regions, multiple large poultry houses are built side by side on affordable land.

Maximum and minimum ventilation

When birds are heavier or during hot summer days, maximum ventilation is needed. Tunnel ventilation is effective for moving large volumes of air and also provides a cooling effect to reduce heat stress.

Minimum ventilation is more difficult to achieve

Especially when birds are young or in winter, it is challenging to distribute enough fresh air evenly throughout wide houses. The biggest challenge is to get air to reach the center of very large poultry houses.

Reaching the center of the house

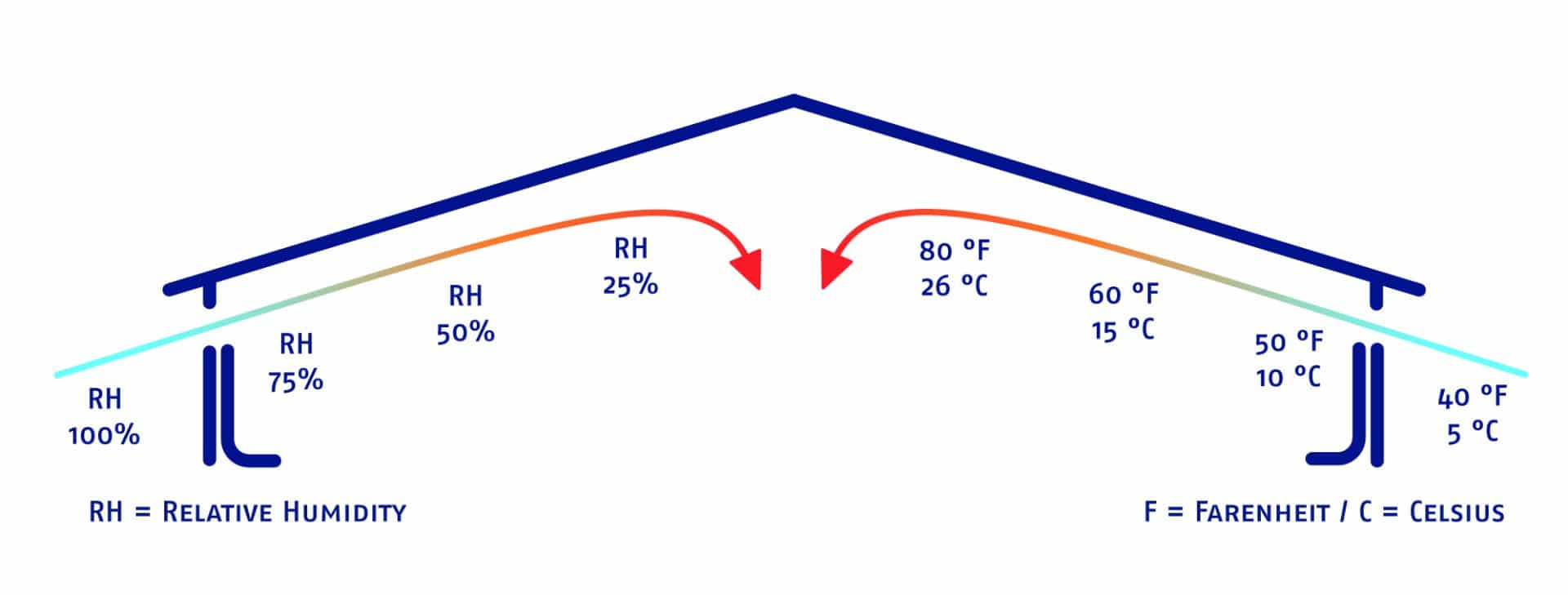

With well-positioned air inlets, fresh air follows the ceiling thanks to the Coanda effect, helping it reach the house’s center. As the air warms, relative humidity drops. This warm, dry air then reaches the birds, dries the litter, and removes harmful gases before exiting.

If air doesn’t reach the center, humidity remains high, causing problems like wet litter, lesions on birds’ feet, and respiratory issues due to gases like ammonia.

Obstacles inside the house

Obstacles inside the house

Support beams and layer nests can block airflow, especially in houses wider than 78ft (24m). Air guides can direct air under beams, and ventilation chimneys bring fresh air from above into hard-to-reach corridors. Diffuser plates prevent cold air from dropping directly on birds. Combining wall inlets with chimneys and tunnel ventilation ensures fresh air reaches all areas.

How ventilation techniques work together for optimal performance:

- Wall inlets direct air towards the ceiling, where the Coanda effect helps it travel far into the house. Concentrating air increases its speed and reach.

- Ceiling inlets suit wide houses by allowing air intake from the attic, where it warms before entering the living area.

- Ventilation chimneys can be used for both exhaust and air intake, equipped with diffuser plates to spread air gently and avoid drafts on birds.

- Circulation fans help distribute air but can disrupt airflow patterns, so their effects should be tested carefully.

- Planning ventilation from the start allows optimal equipment placement, ensuring a stable indoor climate all year round. This leads to healthier birds, better production, energy savings, and peace of mind.

Unique ventilation and climate factors in large houses

Larger houses hold more birds and produce more exhaust gases, which stay near the floor and must be removed efficiently. Multi-tier systems require good ventilation from top to bottom. Advanced computers and sensors help control these complex systems, allowing fine adjustments like individually controlled intake chimneys. Good data and control lead to the best climate management.

Conclusion

The largest poultry houses benefit from a combination of ventilation methods. Wall inlets that bundle air towards the ceiling and the center improve airflow. Ventilation chimneys and ceiling inlets bring fresh air from above, especially important in houses with nesting systems. Tunnel ventilation handles maximum ventilation needs.

Using only one ventilation method year-round isn’t enough for very large houses. Multiple techniques working together, supported by specialized computers and sensors, ensure a smooth transition between minimum and maximum ventilation. Optimal climate control leads to healthier birds, better production, and increased profits. Designing ventilation early in the building process is essential.

Sources:

United States Department of Agriculture

University of Georgia

Zootechnica

“Combining ventilation concepts for very large poultry houses”

By; S.M.H. Jacobs, Marketing Coordinator at TPI-Polytechnics

Den Bosch, 01-10-2021

Obstacles inside the house

Obstacles inside the house