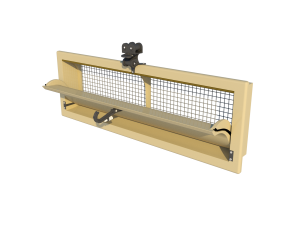

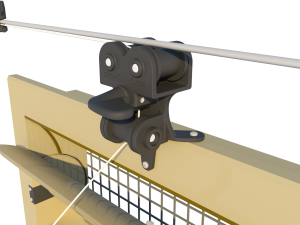

Ventum Luchtinlaat

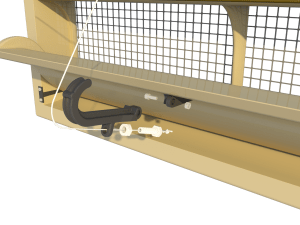

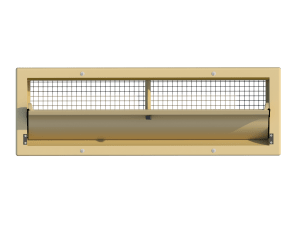

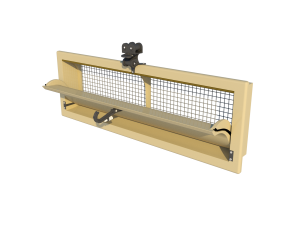

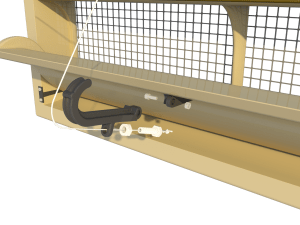

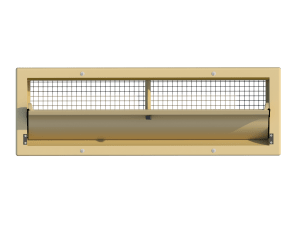

Deze inlaat is ontwikkeld om onze unieke luchtinlaat functies en technologieën beschikbaar te maken voor Amerikaanse bouw- en ventilatieconcepten. De afmetingen van de Ventum zijn op basis van inches, waardoor het gemakkelijk kan worden gebruikt in renovatieprojecten waar bestaande inlaten moeten worden vervangen. Deze inlaat is vooral geschikt voor pluimveestallen, omdat de gebogen binnenklep helpt om de lucht naar beneden te leiden bij maximale ventilatie. De klep en het frame van deze inlaat zijn rondom voorzien van slijtvaste strippen om luchtlekkage te voorkomen en de gebogen binnenhoeken van het frame helpen de luchtinlaat te optimaliseren. Onze unieke polyurethaan formule en het gebruik van luchtafdichtingen zorgen voor een optimale isolatie waardoor de inlaat ideaal is voor extreem lage temperaturen.

Capaciteit in m3/hour bij een statische druk van:

Model | 10Pa | 20Pa | 40Pa |

|---|---|---|---|

Ventum | 3480 | 4900 | 6950 |

Product informatie:

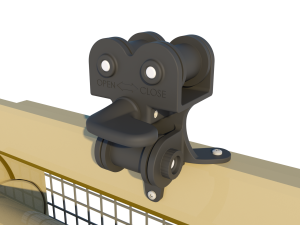

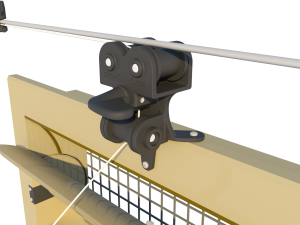

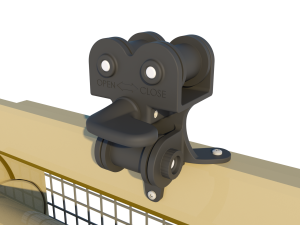

Run | 47 cm / 18.5 Inch |

Force | 3 kg / 29.4 Newton |

Number / pallet | 48 (1.30 x 1.00 x 2.40 m) |

Weight / per inlet | 4.8 kg / 10.6 Lbs |

Volume / per box | 24 |